Question

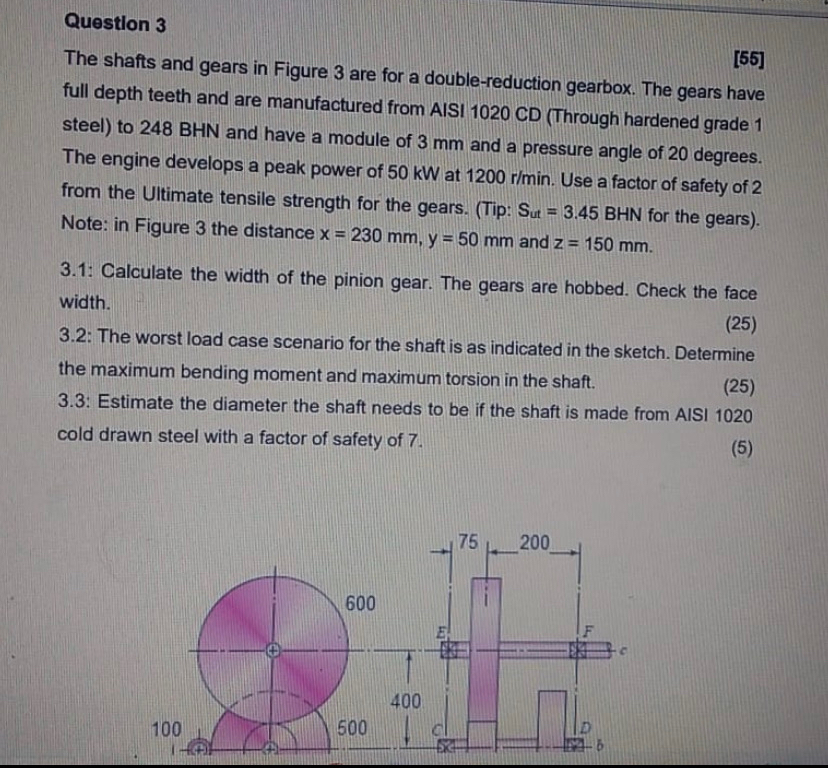

The shafts and gears in Figure 3 are for a double-reduction gearbox. The gears have full depth teeth and are manufactured from AISI 1020 CD (Through hardened grade 1 steel) to 248 BHN and have a module of 3 mm and a pressure angle of 20 degrees. The engine develops a peak power of 50 kW at 1200 r/min. Use a factor of safety of 2 from the Ultimate tensile strength for the gears. (Tip: Sut = 3.45 BHN for the gears). Note: in Figure 3 the distance × = 230 mm, y = 50 mm and z = 150 mm. 3.1: Calculate the width of the pinion gear. The gears are hobbed. Check the face width. 3.2: The worst load case scenario for the shaft is as indicated in the sketch. Determine the maximum bending moment and maximum torsion in the shaft. 3.3: Estimate the diameter the shaft needs to be if the shaft is made from AISI 1020 cold drawn steel with a factor of safety of 7.

Solution

😁